- Process: Casting+Machining+surface treatment(As customers request)

- Surface Treatment: Dacromat Coating, Finish Painting etc. As customers request

- Material Grade: Aluminum alloy,Ductile iron,Grey iron ,steel,stainless steel etc. As customers request

- Package for parts: Multilayer wooden box with big plastic bag inside

- Lead Time: 45-50 days for as customers request

- If you have project that requires customized parts, could you please send us the drawings or samples of the product? We are happy to quote you.

Custom Made Low Pressure Aluminum Casting Inlet Intake Manifold Fabrication Cost

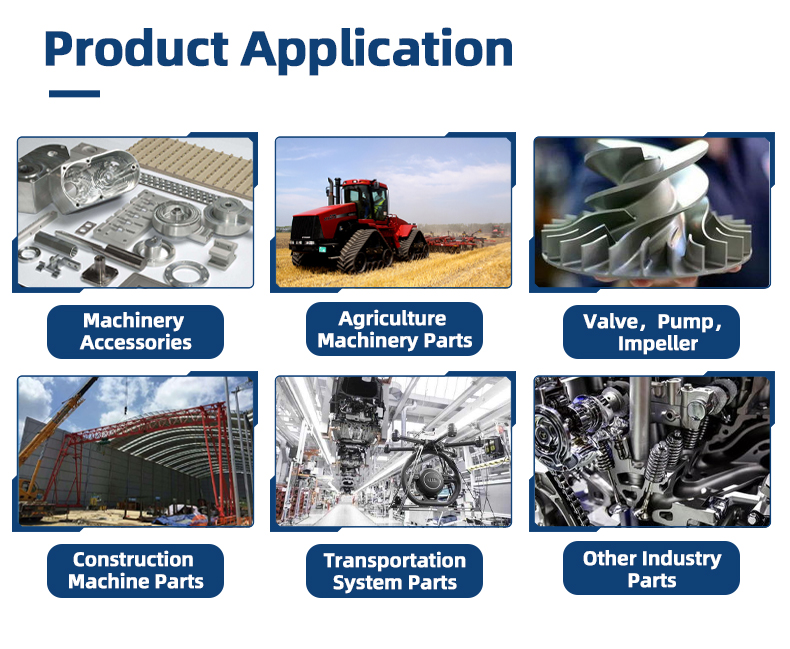

| General Products Application/Service Area | Metal Parts Solution for Vehicle, Agriculture machine, Construction Machine, Transportation equipment, Valve and Pump system, Agriculture machine metal Parts, engine bracket, truck chassis bracket, gear box , gear housing , gear cover, shaft, spline shaft , pulley, flange, connection pipe, pipe, hydraulic valve, valve housing ,Fitting , flange, wheel, flywheel, oil pump housing, starter housing, coolant pump housing, transmission shaft , transmission gear, sprocket, chains etc. |

| Main blank Process for Aluminum Casting | Die Casting, Permanent Molding /Gravity Casting, Low Pressure Casting, High Pressure Casting/Sand Casting, Extrusion Casting etc. |

Blanks Tolerance -Casting Tolerance | CT4-6 for Permanent Molding, Die Casting, CT 9-11 for Sand Casting |

Applicable Material for casting | A356.0/ZL101,GAlSi7Mg (3.2371.61)/AlSi7Mg/, A-S7G, Al Si Alloy, Al Cu Alloy ZL201 Al Mg Alloy ZL301,ZL302, Al Zn Alloy ZL401Zn Alloy Zamak 3, Zamak 5, Zamak 7, Zamak 2Or according to customer requirements |

Casting Blank Size / Dimensions | 2 mm-1500mm / 0.08inch-60inch , or according to customer requirements |

| Casting Blank Weight | Range from 0.01kg-50kg |

Applicable Machining Process | CNC Machining/ Lathing/ Milling/ Turning/ Boring/ Drilling/ Tapping/ Broaching/Reaming /Grinding/Honing and etc. |

| Machining Tolerance | From 0.005mm-0.01mm-0.1mm |

| Machined Surface Quality | Ra 0.8-Ra3.2 according to customer requirement |

| Applicable Heat Treatment | T5~T6 |

Applicable Finish Surface Treatment | Shot/sand blast, polishing, Primer Painting , Powder coating, ED- Coating, Finish Painting, Anodize (White or Black Color) |

MOQ | For casting : 200pcs For Machining: 50pcs |

Lead Time | 45days from the receipt order date |

Gravity casting

Gravity casting refers to the process of injecting molten metal into a mold under the action of the earth's gravity, also called casting.

The generalized gravity casting includes sand casting, metal casting, investment casting, lost foam casting, mud casting,etc. The narrow gravity casting refers specifically to metal casting.

Low-pressure casting

Low-pressure casting is a casting method in which liquid alloy is pressed into the mold cavity from bottom to top under pressure,and solidified under pressure to obtain castings.

The principle of pressure casting is to pass dry compressed air or inert gas into a sealed crucible,

with the help of the pressure acting on the molten metal surface, the molten metal flows along the riser pipe from bottom to top to fill the mold smoothly through the runner ,

The filling pressure is generally 20-60kPa. When the casting is completely solidified,

the gas pressure on the liquid surface is released, so that the non-solidified molten metal in the riser pipe and the runner flows into the crucible by its own weight,

and then the mold is opened and the casting is taken out.

measuring liquid level, sealing test, mold matching, tightening mold or mold, etc.

casting and sand casting, and it is also different from pressure casting with high pressure and high speed filling.

surface of the molten metal, low-pressure casting is filled with molten metal in the lower part of the crucible through the riser pipe, which completely avoids the possibility of molten slag entering the mold cavity.

molten metal, which is beneficial to the formation of castings with clear contours and smooth surface, and is more beneficial for the molding of large thin-walled castings.

Technical Support:

Shanghai Matech is professional at independent development and design. Our engineers are skilled at AUTO CAD, PRO ENGINEER, SOLID WORKS and other 2D & 3D softwares.

We are able to design, develop,produce and deliver your PO according to your drawings, samples or just an idea. Dural control of standard products and OEM products.

Quality Control:

1) Checking the raw material after they reach our factory------- Incoming quality control ( IQC)

2) Checking the details before the production line operated

3) Have full inspection and routing inspection during mass production---In process quality control(IPQC)

4) Checking the goods after they are finished---- Final quality control(FQC)

5) Checking the goods after they are finished-----Outgoing quality control(OQC)

Shanghai Matech Machinery Manufacture Co., Ltd.

--Branch of Matech Industry Ltd.

We specialize in Metal Parts Solution for Vehicle, Agriculture machine, Construction Machine, transportation equipment, Valve and Pump system etc.

With keeping manufacturing process design, quality planning, key manufacturing processes and final quality control in house. We are mastering key competence to supply quality mechanical

parts and assembly to our customers for both Chinese and Export Market.

To satisfy different mechanical and functional requirements from our customers. We are making a big range of metal products for our clients on base of different blanks solutions and

technologies. These blanks solutions and technologies include processes of Aluminum Casting.

During the early involvement of the customer's design process we are giving professional input to our customers in terms of process feasibility, cost reduction and function approach.

You are welcome to contact us for technical enquiry and business cooperation.

Material:aluminum ZL101,A356, A360,A380 or as customer‘s requirements.Process: Casting +Machining(if Need)+surface Treatment