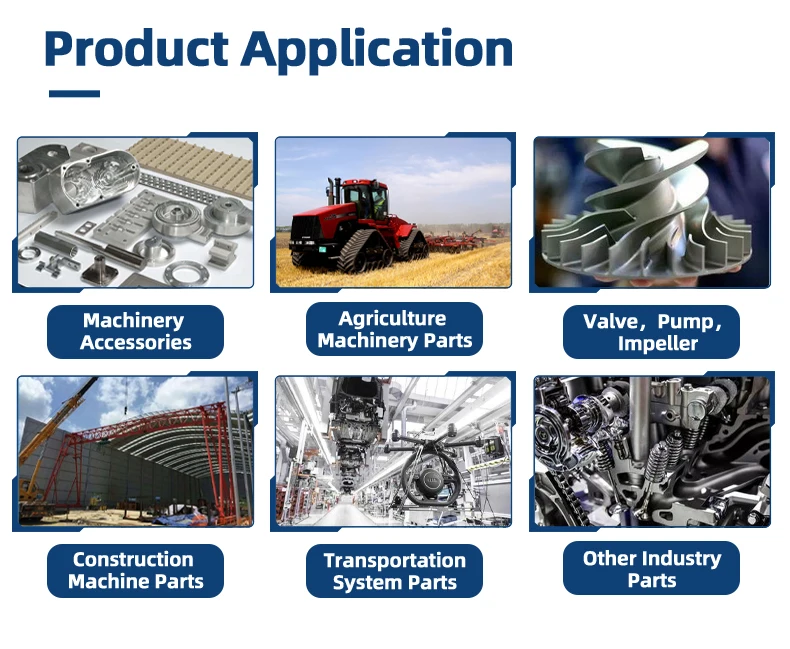

Product name | Customized Service High Performance Track Chains Forged Steel |

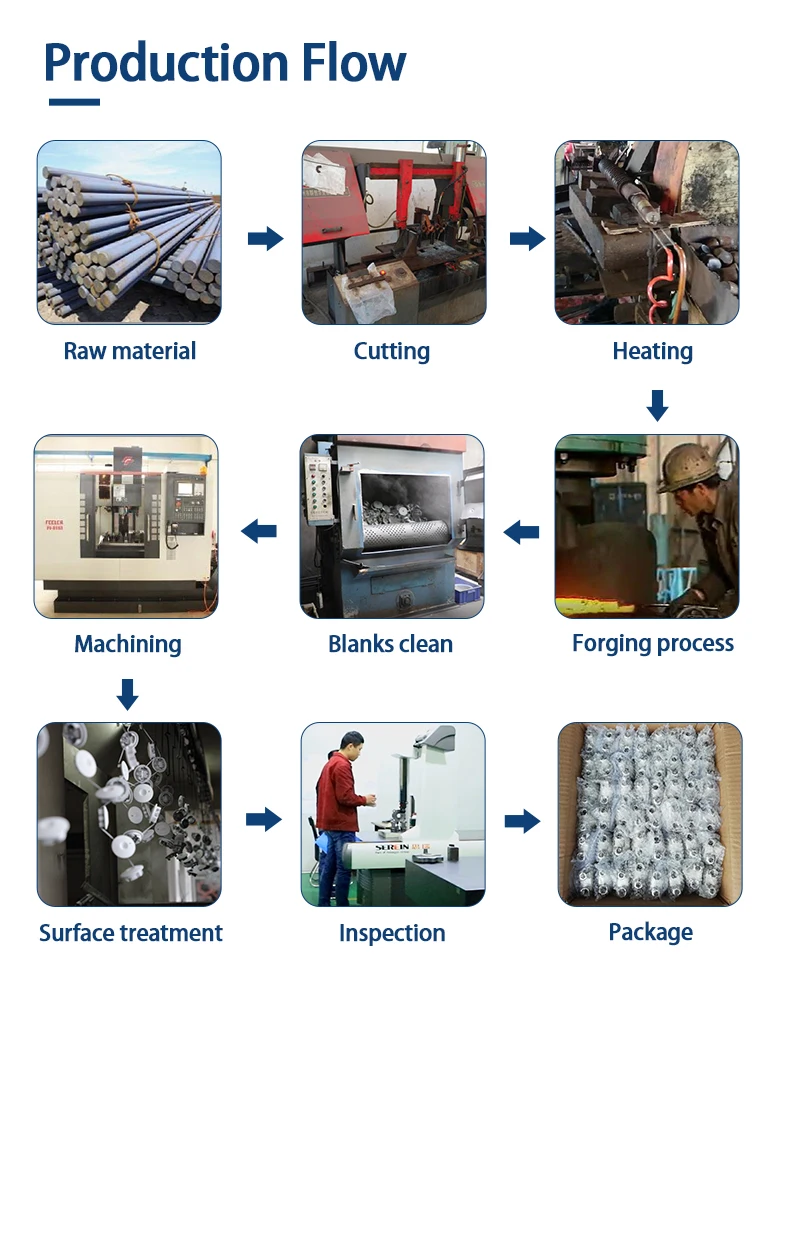

Production Process for Forged parts | Forging, press, plus machining ,heat treatment , assembly |

Blanks Tolerance: | +/-0.3~+/-2 mm |

Production Applicable Material: | Stainless steel: 303, 304, 316L, etc |

Steel: 4140, Q235, Q345B, 20#, 45#, etc |

Aluminum: AL 6061-T6, 6063, 7075-T, etc |

Forging Blank Size /Dimensions: | 142 mm- 300mm or according to customer requirement |

Blanks Weight: | Range from 0.1kg-1000kg for track chains forged steel |

Applicable Machining Process: | CNC Machining/ Lathing/ Milling/ Turning/ Boring/ Drilling/ Tapping/ Broaching/Reaming etc. |

Machining Tolerance: | From 0.005mm-0.01mm-0.1mm |

Machined Surface Quality: | Ra 0.8-Ra3.2 according to customer requirement |

Applicable Heat Treatment: | Normalization , quenching and tempering, Case Hardening, Nitriding, Carbon Nitriding, Induction Quenching |

Applicable Finish Surface Treatment: | Shot/sand blast, polishing, Surface passivation, Primer Painting , Powder coating, ED- Coating, Chromate Plating, zinc-plate,

Dacromat coating, Finish Painting,for stainless steel forg |

MOQ of mass production: | For forging parts: 500 PCs

For Machining: 50 Pcs |

Lead Time: | 30-40 days from the receipt date of track chains forged steel |