- Material: Aluminum or other metal. As clients require

- Manufacturing Process: casting, machining

- MOQ: 1pc sample for test is available

- Lead Time: About 40 days for casting

- Package of stamping: Multilayer wooden box with big plastic bag inside, as customer request

- Service: Custom Make Part with factory price

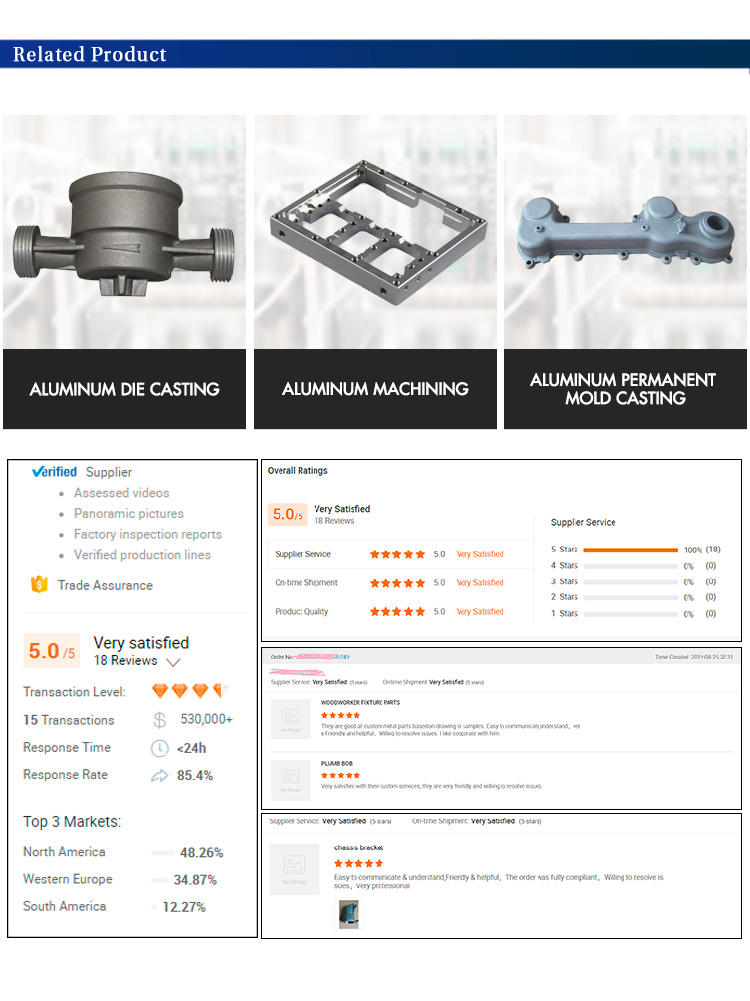

China Supplier Precision Customized Cast Pipe Fitting

| Product Name | China Supplier Precision Customized Cast Pipe Fitting |

| Main blank Process | Die Casting |

| Blanks Tolerance -Casting Tolerance | CT4-6 for Die Casting |

| Applicable Material for Die casting | Zn Alloy Zamak 3, Zamak 5, Zamak 7, Zamak 2; A380 ADC12 aluminum casting part; Or according to customer requirements |

| Casting Blank Size /Dimensions | 2 mm-1500mm / 0.08inch-60inch , or according to customer requirements |

| Applicable Machining Process | CNC Machining/ Lathing/ Milling/ Turning/ Boring/ Drilling/ Tapping/ Broaching/Reaming /Grinding/Honing and etc. |

| Machining Tolerance | From 0.005mm-0.01mm-0.1mm |

| Machined Surface Quality | Ra 0.8-Ra3.2 according to customer requirement |

| Applicable Finish Surface Treatment | Shot/sand blast, polishing, Primer Painting , Powder coating, ED- Coating, Finish Painting, Anodize (White or Black Color), as customers request. |

| Lead Time | 45 days for die casting fitting corner quick coupling connectors |

1. What do you do?

We are a professional manufacturer with over 15 years' export experience for designing and producing vehicle machinery parts.

2. Can you make fitting corner according to our drawing?

Yes, we can make fitting corner according to your drawing, 2D drawing, or 3D cad model. If the 3D cad model can be supplied, the development of the tooling can be more efficient. But without 3D, based on 2D drawing we can still make the samples properly approved.

3.How can I get some samples?

If you need, we are glad to offer you samples for free, but the new clients are expected to pay the courier cost, and the charge will be deducted from the payment for formal order.

4.Can you make die casting fitting corner based on our samples?

Yes, we can make measurement based on your samples to make drawings for tooling making.

5.What's your quality control device in house?

We have spectrometer in house to monitor the chemical property, tensile test machine to control the mechanical property and UT Sonic as NDT checking method to control the casting detect under the surface of die casting fitting corner.

Contact us now

We produce metal parts, pipe fitting, brackets, housings, shafts etc., and focus on cost reduction and feasible tech proposal