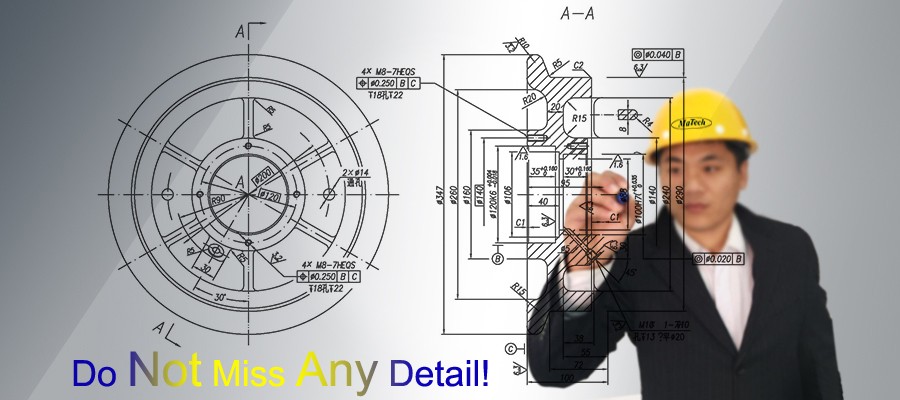

OEM Customized Machine Parts Shaft Machining

- Brand Name: MATECH

- Type: Broaching, DRILLING, Etching / Chemical Machining, Laser Machining, Milling, Other Machining Services, Turning, Wire EDM, Rapid Prototyping

- Material Capabilities: Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, Stainless Steel, Steel Alloys

- Application: CNC machining parts for Vehicle Machinery and industrial field

- Custom Made Service: YES, machining parts per your drawings or samples

- Machining Process: CNC Machining/ Lathing/ Milling/ Turning/ Boring/ Drilling etc.

- Machining Tolerance: Up to IT7, Ra 0.8~3.2 , according to customer requirement

- Surface treatment: Surface passivation, polish etc. As customers request

- Packing: Multilayer wooden box/pallet, with big plastic bag inside

- Lead time: 25 days for bending aluminum tube

- Welcome to contect us!

- Jessica's Email:matech011@matechin.com

OEM Customized Machine Parts Shaft Machining

Product Description

Factory Show

Technical Support:

Shanghai Matech is professional at independent development and design. Our engineers are skilled at AUTO CAD, PRO ENGINEER, SOLID WORKS and other 2D & 3D softwares. We are able to design, develop,produce and deliver your PO according to your drawings, samples or just an idea. Dural control of standard products and OEM products.

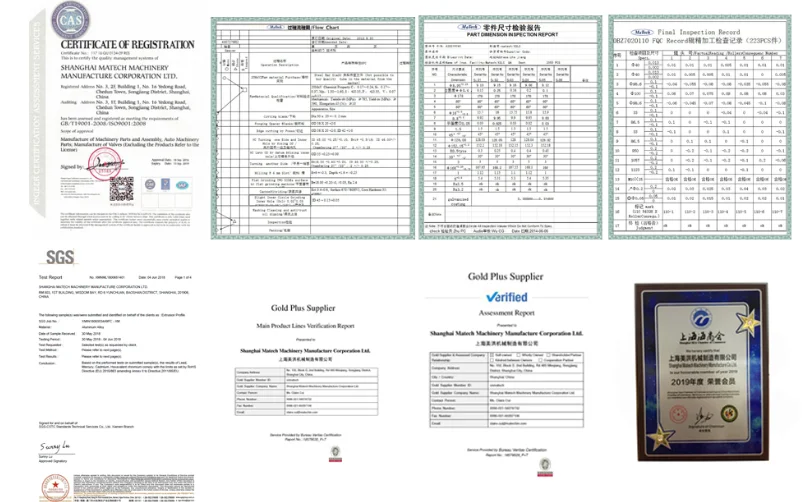

Quality Control:1) Checking the raw material after they reach our factory------- Incoming quality control ( IQC)

2) Checking the details before the production line operated

3) Have full inspection and routing inspection during mass production---In process quality control(IPQC)

4) Checking the goods after they are finished---- Final quality control(FQC)

5) Checking the goods after they are finished-----Outgoing quality control(OQC)

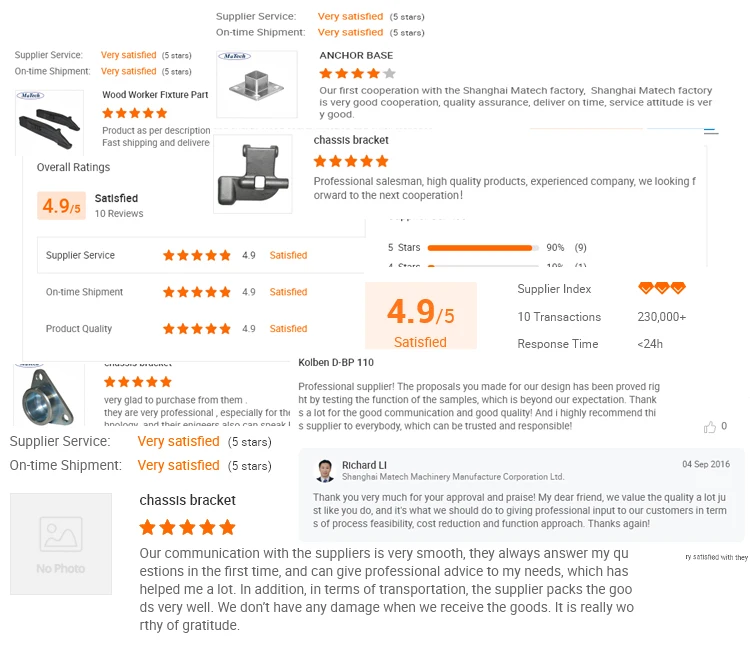

Customers & Family

Our customers have become our friends, also what we call family members. welcome to join us!!!

Our Team are a big happy family, we not only supplying products to our customers , but also trying to build more values to our customers’ business by introducing suitable solution or technology to our customers with compromising parts’ function, technologies’ advantage, realization feasibility, cost control and quality reliability.

Our Core Value : Sincerity Quality Competence

Exhibition

Product packaging

Inner Packing →Strong & waterproof plastic big is packed inside, to keep the product in safe condition.Or as customer requests.

Outer Packing →Multilayer wooden box with strong bandages, used for standard export package. Or customized as per customer's requirements.

Outer Packing →Multilayer wooden box with strong bandages, used for standard export package. Or customized as per customer's requirements.

FAQ

1. What do you do?

We are a professional manufacturer with over 15 years’ export experience for designing and producing vehicle machinery parts. Focus on saving cost, function approach, production feasibility for your projects.

2. How can I get some samples?

If you need, we are glad to offer you samples for free, but the new clients are expected to pay the courier cost, and the charge will be deducted from the payment for formal order.

3. Can you make machine parts shaft machining according to our drawing?

Yes, we can make machine parts shaft machining according to your drawing, 2D drawing, or 3D cad model. If the 3D cad model can be supplied, the development of production can be more efficient. But without 3D, based on 2D drawing we can still make the samples properly

approved.

4. Can you make machine parts shaft machining based on our samples?

Yes, we can make measurement based on your samples to make drawings for machining parts making.

5. What’s your quality control device in house?

We have spectrometer in house to monitor the chemical property, tensile test machine to control the mechanical property and UT Sonic as NDT checking method to control the casting detect under the surface.

2. How can I get some samples?

If you need, we are glad to offer you samples for free, but the new clients are expected to pay the courier cost, and the charge will be deducted from the payment for formal order.

3. Can you make machine parts shaft machining according to our drawing?

Yes, we can make machine parts shaft machining according to your drawing, 2D drawing, or 3D cad model. If the 3D cad model can be supplied, the development of production can be more efficient. But without 3D, based on 2D drawing we can still make the samples properly

approved.

4. Can you make machine parts shaft machining based on our samples?

Yes, we can make measurement based on your samples to make drawings for machining parts making.

5. What’s your quality control device in house?

We have spectrometer in house to monitor the chemical property, tensile test machine to control the mechanical property and UT Sonic as NDT checking method to control the casting detect under the surface.

Welcome to contact us for more details