Forging Plant

Forging is a processing method that uses forging machinery to exert pressure on metal blank to make it plastic deformation to obtain forgings with certain mechanical properties, shape and size.Forging can eliminate as cast porosity and other defects produced in the smelting process of metal, optimize the microstructure. At the same time, due to the preservation of complete metal streamline, the mechanical properties of forgings are generally superior to castings of the same material.

According to the forging temperature, it can be divided into hot forging, warm forging and cold forging.Forgings used in most industries are hot forging. Warm forging and cold forging are mainly used for forging parts such as automobiles and general machinery.

Forging materials are mainly carbon steel and alloy steel with various compositions, followed by aluminum, magnesium, copper, titanium, etc. and their alloys.

Main Blank Process: | Forging press, hot forging, cold forging |

| Applicable Material: | Alloy forging steel 42CrMo; 4140 OR According to customer’s requirement |

| Forging Blank Size: | 2 mm-600mm / 0.08inch-24inch according to customer requirement |

| Casting Blank Weight: | Range from 0.01kg-85kg |

| Applicable Machining Process: | CNC Machining/ Lathing/ Milling/ Turning/ Boring/ Drilling/ Tapping/ Broaching/Reaming /Grinding/Honing and etc. |

| Machining Tolerance: | From 0.005mm-0.01mm-0.1mm |

| Machined Surface Quality: | Ra 0.8-Ra3.2 according to customer requirement |

| Applicable Heat Treatment: | Normalization , annealing, quenching and tempering, Case Hardening, Nitriding, Carbon Nitriding, Induction Quenching etc. |

| Applicable Finish Surface Treatment: | Shot/sand blast, polishing, Surface passivation, Primer Painting , Powder coating, ED- Coating, Chromate Plating, zinc-plate, Dacromat coating, Finish Painting, etc. |

| MOQ for batch order: | For forge piece: 100pcs or as client require Or as customers require |

Lead Time: | 50 days for forge piece |

Matech Industry ltd specializes in Metal Parts Solution for Vehicle, Agriculture machine, Construction Machine, transportation equipment, Valve and Pump system.

To satisfy different mechanical and functional requirements from our customers we are making a big range of metal products for our clients on base of different blanks solutions and technologies. These blanks solutions and technologies include processes of Iron Casting, Steel Casting, Stainless Steel Casting, Aluminum Casting and Forging.

During the early involvement of the customer's design process we are giving professional input to our customers in terms of process feasibility, cost reduction and function approach. You are welcome to contact us for technical enquiry and business cooperation.

We have very strict quality control process:

In coming Quality control (IQC) – All incoming raw material are checked before used.

In process quality control (IPQC) – Perform inspections during the manufacturing process.

Final quality control (FQC) – All finished goods are inspected according to our quality standard for each products.

Outgoing Quality Control (OQC) – Our QC team will 100% full inspection before it goes out for shipment.

Proper Quarantine procedure – For those products got rejected to pass the quality control, they will specially marked and dispose.

Providing Casting service according to your needs or your drawings,produce the product you need.

INNER PACKING OUTER PACKING

Strong & Waterproof plastic bag is packed inside, Mutilayer wooden box with strong bandages,

to keep the product in safe condition. Used for standrad export package.

↓↓↓Get A Free Accurate Quote ↓↓↓

FAQ

Q: What do you do?

A: We are a professional forging manufacturer with over 15 years' export experience for designing and producing vehicle machinery parts.

Q: Can you make forging parts based on our samples?

A: Yes, we can make measurement based on your samples to make drawings for forging parts making.

Q: Can you make forging according to our drawing?

A: Yes, we can make forging according to your drawing, 2D drawing, or 3D cad model. If the 3D cad model can be supplied, the development of the tooling can be more efficient. But without 3D, based on 2D drawing we can still make the samples properly approved.

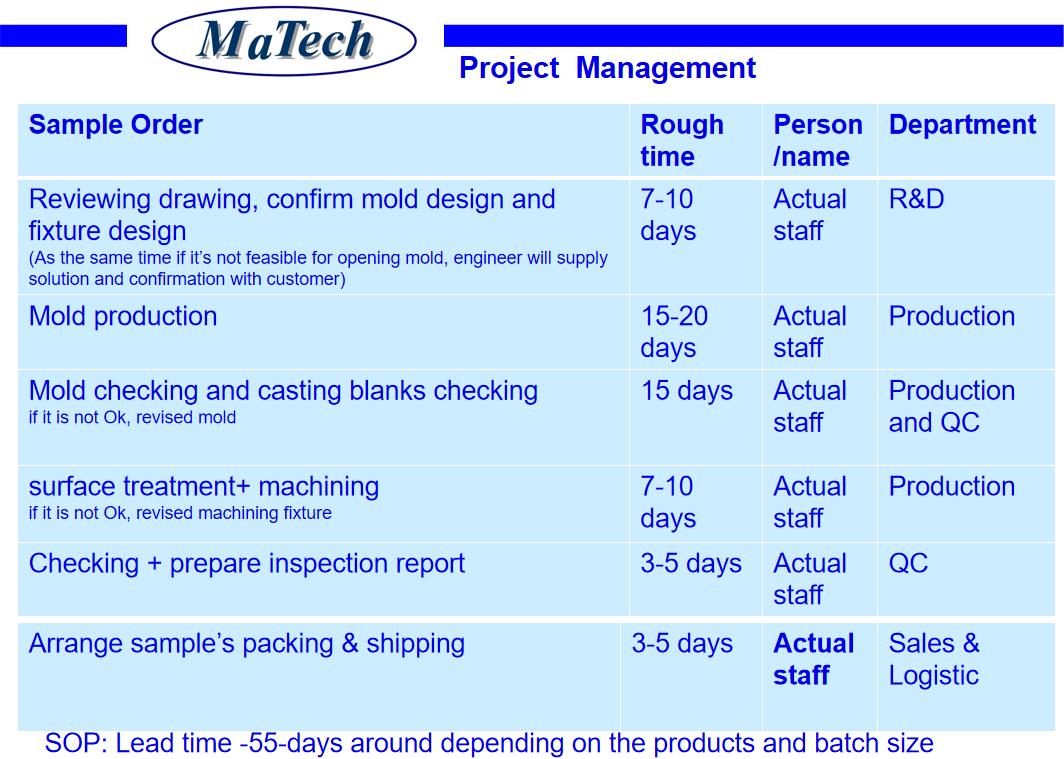

Q:What is the specific production process?

A: drawings designing→Smelting&alloying→QC→forging→remove burrs→QC→Surface treatment→QC→Packing→QC→Shipping→After Sale Service.