Aluminum Casting Plant

Common aluminum casting methods include die casting, low pressure casting, precision casting , sand casting and permanent mold manufacturing.

Just tell us your needs, and we have a professional team to designate a complete one-stop solutions for you, including the best materials and processes, to best meet your requirements.YOUR DESIGN WE HELP TO ACHIEVE,AS YOUR SINCERE PARTNER!

At MATECH, we want to exceed your expectations by delivering the most economical solution for your product manufacturing needs. We do this by constantly evolving what we do, and finding new ways to improve your current products, that will ultimately drive down costs and increase overall performance.

Welcome your inquiry at any time.

DIE CASTING PLANT

Die casting is a metal casting process, which is characterized by applying high pressure to the molten metal using the cavity of the mold. Molds are usually made of higher-strength alloys, and this process is somewhat similar to injection molding. Most die castings are iron-free, such as zinc, copper, aluminum, magnesium, lead, tin, and lead-tin alloys and their alloys. Depending on the type of die casting, you need to use a cold chamber die casting machine or a hot chamber die casting machine. The cost of casting equipment and molds is high, so the die-casting process is generally only used for mass production of a large number of products. Manufacturing die-cast parts is relatively easy, which generally only requires four main steps, and the individual cost increment is very low. Die casting is particularly suitable for manufacturing a large number of small and medium-sized castings, so die casting is the most widely used one among various casting processes. Compared with other casting technologies, the die-casting surface is flatter and has a higher dimensional consistency.

Some pictures of our parts:

Providing Casting service according to your needs or your drawings,produce the product you need.

LOW PRESSURE CASTING PLANT

Low-pressure casting

measuring liquid level, sealing test, mold matching, tightening mold or mold, etc.

casting and sand casting, and it is also different from pressure casting with high pressure and high speed filling.

surface of the molten metal, low-pressure casting is filled with molten metal in the lower part of the crucible through the riser pipe, which completely avoids the possibility of molten slag entering the mold cavity.

molten metal, which is beneficial to the formation of castings with clear contours and smooth surface, and is more beneficial for the molding of large thin-walled castings.

GRAVITY CASTING PLANT

Gravity casting

Price-- Competitive.We know the market situation.

Quality-- Quality Assurance and Quality Improvement.We know the importance of material chemical composition,tolerances.

Delivery time-- Time Guarantee. We know the loss of our customer when we delay.

Excellent Service-- 24hours answer.72hours quotation.We answer for any quality issue,if there will be any.

1. Over 15 years professional manufacture experience. → We know better to your needs.

2. One-stop Service of Custom mold design from Initial drawing design, Material selection assistance, Mold structure/Mold flow

analysis, Trial & mass production to Final assembly & shipment. → To ensure you get finished products with good assembly function.

3. High skilled and well-trained working team under good management environment. → To make sure high quality of your products.

4. Large and strong production capacity. → To meet your high demands very well.

5.Best price based on same quality requirements. →To help your project with most economical solution.

6. We have very strict quality control process included IQC/IPQC/FQC/OQC. → To deliver the qualified products for you.

7.Reliable Package & flexible in-time delivery. →To guarantee the product are well received in your side.

8. 24 hours on-line service with quick response. → To support your any inquiry or question

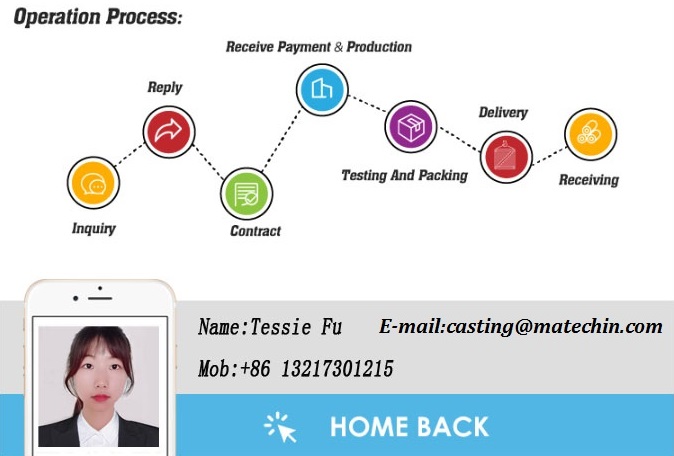

Packing & Delivery (Show As Above):

Inner Packing →Strong & waterproof plastic big is packed inside, to keep the product in safe condition.Or as customer requests.

Outer Packing →Multilayer wooden box with strong bandages, used for standard export package. Or customized as per customer's requirements.

↓↓↓Get A Free Accurate Quote ↓↓↓